the ALL ELECTRICAL PORSCHE 964 RSR-ev

Welcome to the revitalized journey of a classic – Project 964 RSR-e Tribute.

When innovation meets history, we get a symphony of modernity wrapped in the essence of a classic. This project embodies the crossroads of passion, technology, and sustainability. We're not merely resurrecting a 30-year-old legend; we're infusing it with a modern heartbeat. Our mission? To retain the soul, feel, look, and driving experience of the iconic Porsche 964 RSR, while crafting it with a tapestry of Carbon fiber and a medley of meticulously 3D printed Onyx components.

Why take on such a monumental task?

Because we believe in challenging the boundaries. We're not only making a statement about the prowess of modern engineering; we're showcasing that technology can harmoniously coexist with sustainability. This electrified tribute will retain its legendary performance, reimagined with a conscientious approach to the environment. Every charge, every drive, will draw purely from the benevolent energy of the sun, thanks to our dedicated solar panels.

The pandemic may have introduced hurdles, but it's only bolstered our determination. With Brink Motorsport as our esteemed collaborator, we are fast-tracking towards our vision. Stay tuned, as we accelerate towards our completion goal in early 2024. Dive into this electric odyssey with us, and witness the fusion of past, present, and future.

HUNTING KILOGRAMS

SCULPTING LIGHTNESS

Our Porsche 964 RSR EV Weighs in

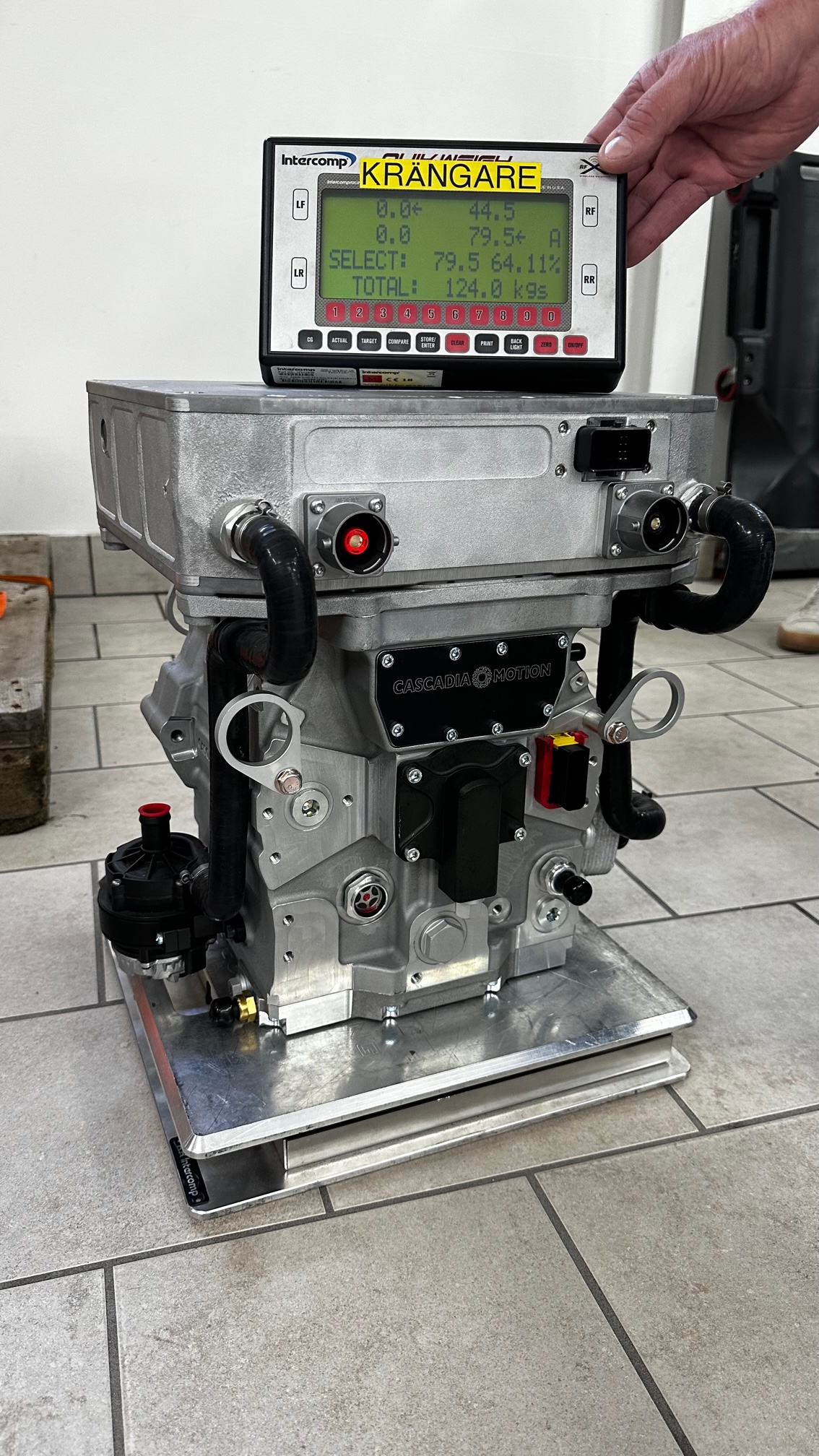

In the realm of electric vehicles, weight becomes a defining parameter. Our journey with the Porsche 964 RSR EV was guided by the singular ambition of achieving the best weight-to-power ratio, without compromising on the spirit of the iconic RSR.

From our starting point with the 1447 Kg 964 Carrera C4, with its inherent 42/58 weight distribution, we infused modern innovation and design. The introduction of the RSR tribute Carbon fiber bodywork was our first masterstroke, shedding off 100 Kg. With the removal of the combustion engine, gearbox, and other traditional components, we saw a dramatic weight drop, placing us at a mere 735 Kg. Yet, the addition of the purpose-built aluminum battery box and its 14 cells took our tally to 918 Kgs.

What sets our project apart isn't just the engineering finesse but the comparative brilliance. A typical Tesla Model S, often revered for its technology, weighs in around 2000-2300 Kg. Contrast this with our ambition for the RSR EV, and we're aiming for a ballpark weight close to 1200 Kg. The pinnacle of our aspirations? A weight of 1147 Kg. Achieving this would mean our electric marvel is not just a match, but 300 Kgs lighter than its combustion engine ancestor, and with a power output of 381 Hp to boot.

In the contemporary EV landscape, where heavyweight giants dominate the roads, our Porsche 964 RSR EV endeavors to stand out, not merely in horsepower, but in the meticulous attention paid to every kilogram, redefining the essence of performance and sustainability.

DESIGN CONCEPT DRAFT

ACOUSTIC CONCEPT

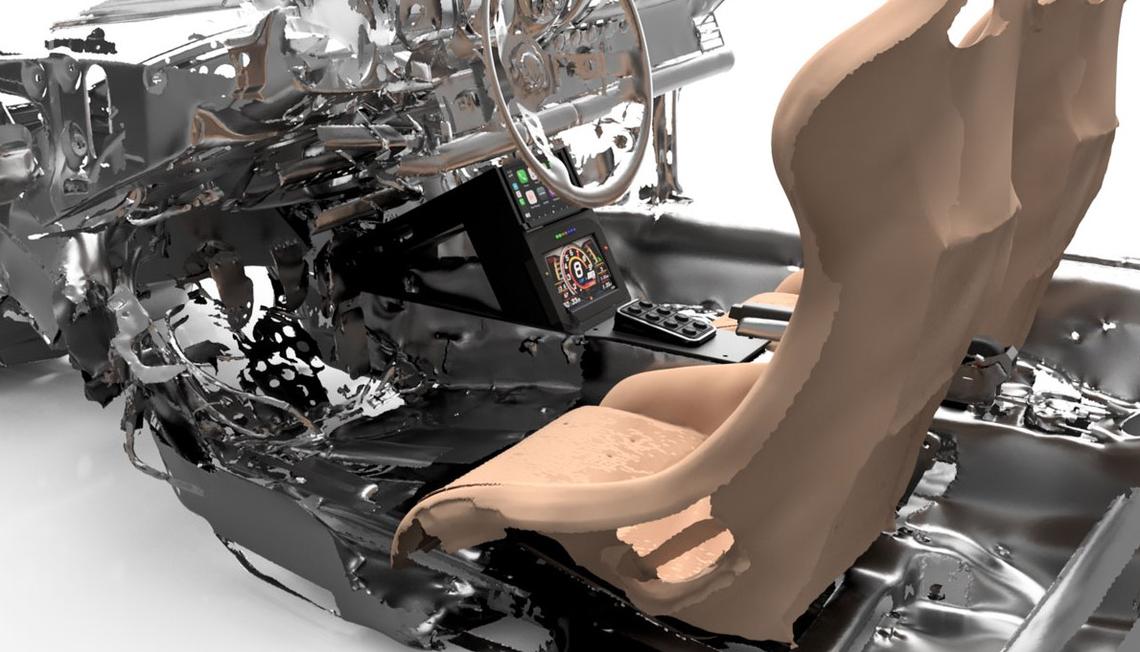

On winding roads, with the engine purring silently, what we need are some rock 'n roll anthems to complement the ride!

Partnering with HiFi brand Infinite Acoustics, we've embarked on creating a virtual loudspeaker and media solution for the car. Our focus is on using top-notch components like high-quality poly capacitors and handmade air coils as first-level crossovers. By incorporating high-quality carbon fiber drivers, we aim to enhance the Porsche RSR's soundscape, delivering a clear and vibrant audio experience.

3D PRINTED PROTOTYPES AND BATTERIES

FINAL BATTERY INSTALLATION

Redefining the Classic Porsche Experience with Modern Engineering

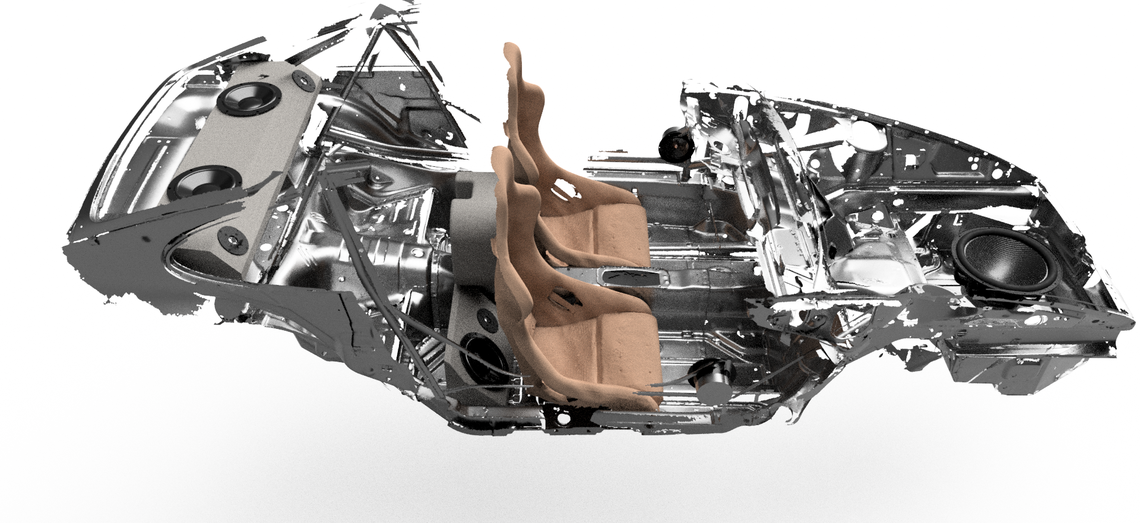

When you think of a classic Porsche 964, it’s not just about the sleek design or the brand's prestige, but also about the unique driving experience it offers. For enthusiasts, it's the weight distribution, the balance, and the roar of the engine – elements that conjure up a nostalgia that's deeply rooted in automotive history.

However, blending modern technology with this classic beauty, while retaining its original charm, is a meticulous balancing act. At the heart of our endeavor with the Porsche EV-RSR project was a singular vision: to fuse the Porsche's classic experience with the advantages of an electric powertrain, without compromising on its legendary weight distribution.

After rigorous simulations and design iterations, the decision to place all the battery packs inside the Brink Motorsport-developed crash box was born out of necessity and innovation. And while this decision transformed the 964 from a 2+2 to a dedicated two-seater, we believe that the enhancements in performance, safety, and driving experience will be the payoff that true Porsche aficionados will appreciate. Especially when considering the limitations of the original rear seats.

Using our 3D printed prototypes, we’ve laid out the foundation for the final engine, gearbox, and battery placements. This process allowed us to visualize, iterate, and perfect the setup before investing in the actual components – a testament to the merging of classic craftsmanship with modern technology.

REIMAGINING AUTOMOTIVE MANUFACTURING:

THE ERA OF 3D PRINTING

One of the primary challenges in the world of automotive engineering has always been creating robust, durable, and adaptable components that can endure the rigorous demands of the road. But as technology propels us into a new era, we're pioneering innovative approaches that marry tradition with state-of-the-art methodologies. Enter our 3D print farm, equipped with over 20 Markforged Onyx 3D printers, our latest weapons in the war against conventionality.

THE DAWN OF THE ELECTRICAL ERA:

OUT WITH THE OLD,

IN WITH THE NEW

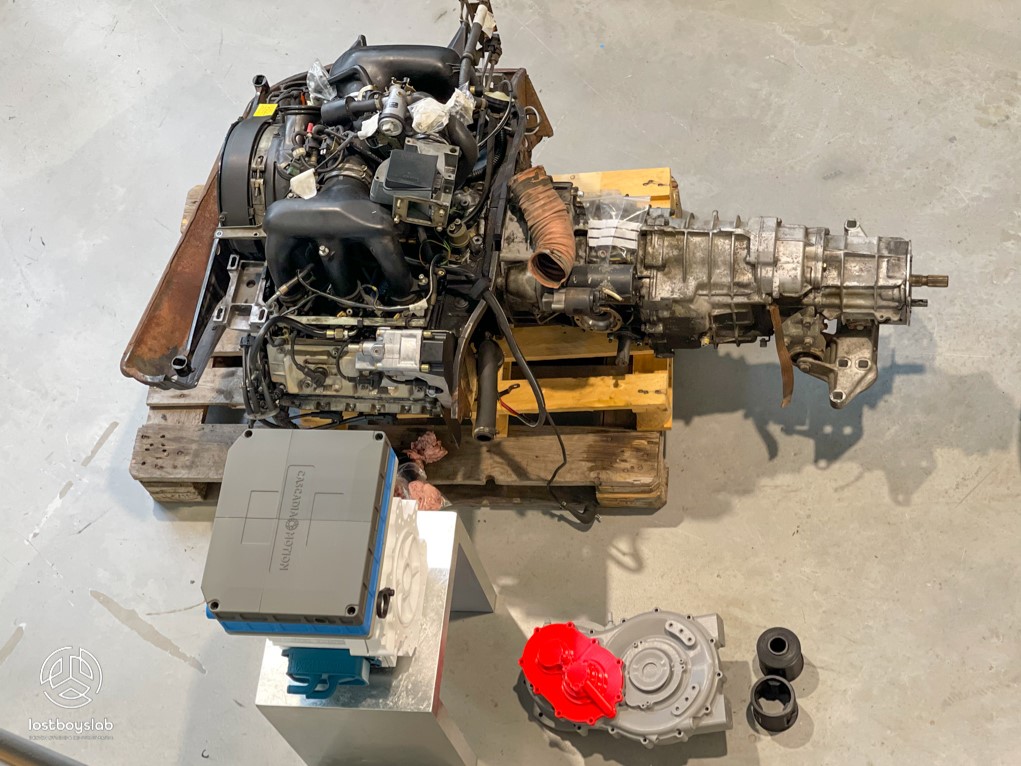

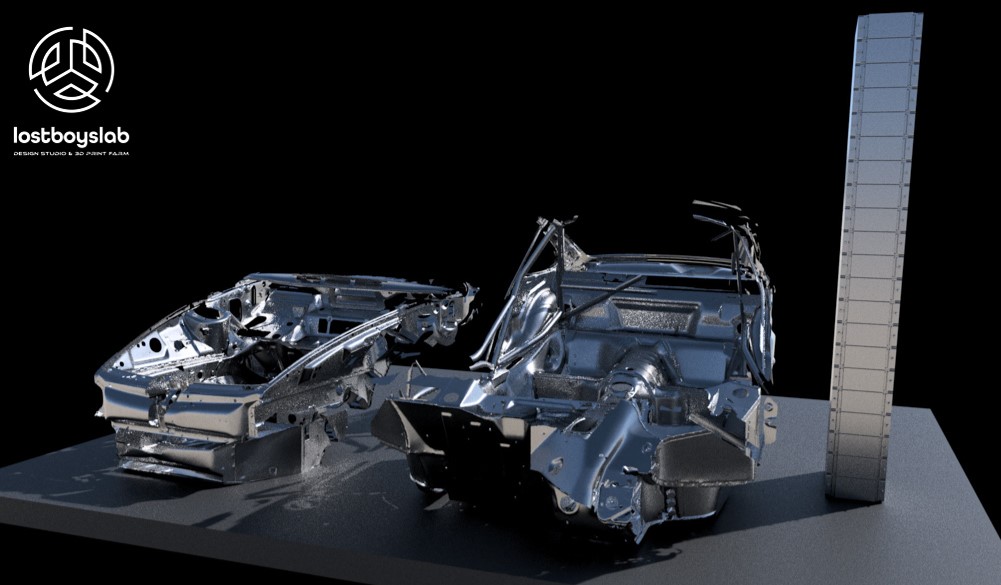

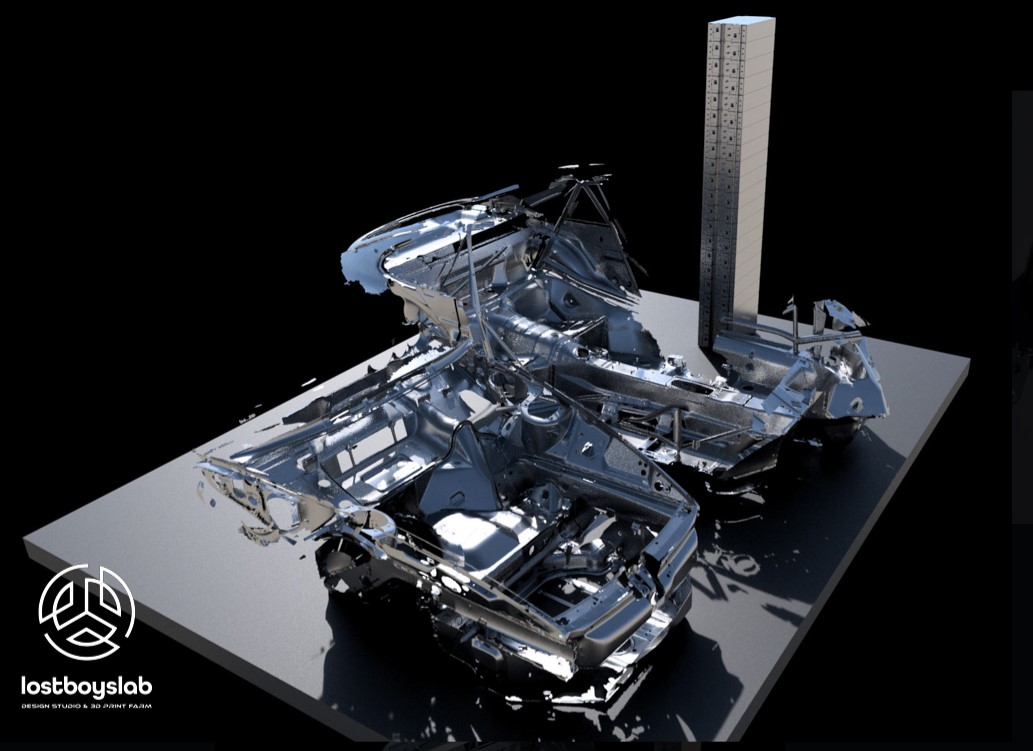

Last night marked a significant milestone in our journey. With skilled hands and precision, we bid farewell to the vintage combustion engine and gearbox, extracting it from its home of decades. As it was hoisted and removed, a striking comparison emerged. Standing next to its streamlined, sleek electric successor, the combustion engine looked like a relic from another age.

The intricacies, complexities, and sheer bulk of the combustion mechanism starkly contrasted with the clean, minimalist design of the electric motor. It’s astonishing to realize that for over a century, we've relied on such a convoluted system. One can't help but wonder: Were we ensnared in a web of familiar comfort, blind to the untapped potential of simpler, more efficient technologies?

Elon Musk and Tesla have undeniably paved the way, igniting a revolution that challenges the automotive status quo. Their daring vision has emboldened enthusiasts and engineers worldwide, including us, to reconsider the norm and explore cleaner, more sustainable alternatives.

The sheer difference in footprint between the two engines is a testament to more than just technological evolution. It's a poignant reminder of the excesses of the past, urging us to tread more mindfully as we race into the future. Yes, the planet might outlive us, but we owe it to future generations to leave a legacy that’s both innovative and conscious.

FROM PIXELS TO REALITY

PROTOTYPING THE ELECTRICAL POWERHOUSE

In our quest to bring the Porsche 911 EV-RSR vision to life, transitioning from the digital realm to tangible prototypes remains an essential step. For us, everything requires a tangible counterpart during this transformative phase.

Enter our meticulously 3D printed Cascadia engine, a true marvel of modern engineering, rendered in over 30 distinct parts. Complementing this is the BorgWarner gearbox, split into three detailed components. While most elements have been materialized using recycled PLA, certain crucial components benefit from the robust ONYX material printed on our advanced Markforged machines.

As the RSR donor car is gradually relieved of its classic combustion remnants – from its vintage powertrain to the time-tested gears and electronics – our 3D printed proxies are proving invaluable. These stand-ins pave the way for the actual assembly, guiding our design and implementation decisions.

BALANCING POWER AND PRECISION:

THE BATTERY CHALLENGE

As we embark on the electrifying journey of embedding the 21 battery cells into our beloved Porsche 911 EV-RSR, we're faced with a complex puzzle - a dance between power and weight distribution, as vividly showcased in our 3D visualizations.

Tipping the scales at 210 kilograms for the entirety of the cells, the overarching aim is to strike that perfect balance, retaining the distinct 911 sensation with an ideal weight spread of 62% at the rear and 38% upfront. As we gear up to harness the might of an 823 Volt system, we're looking at a whopping total of 35.7 kW/h. The sheer power at our fingertips? An exhilarating 525 kW!

But, amidst this electrified enthusiasm, emerges a fundamental question, one that will shape our endeavors throughout the summer: Is raw power truly the endgame? By dialing down the horsepower to align with the original RSR's 360 Hp, we could potentially trim our battery count down to 14, shedding 70Kg off our total weight. Is the pursuit of authentic homage perhaps a more worthy aspiration than sheer force?

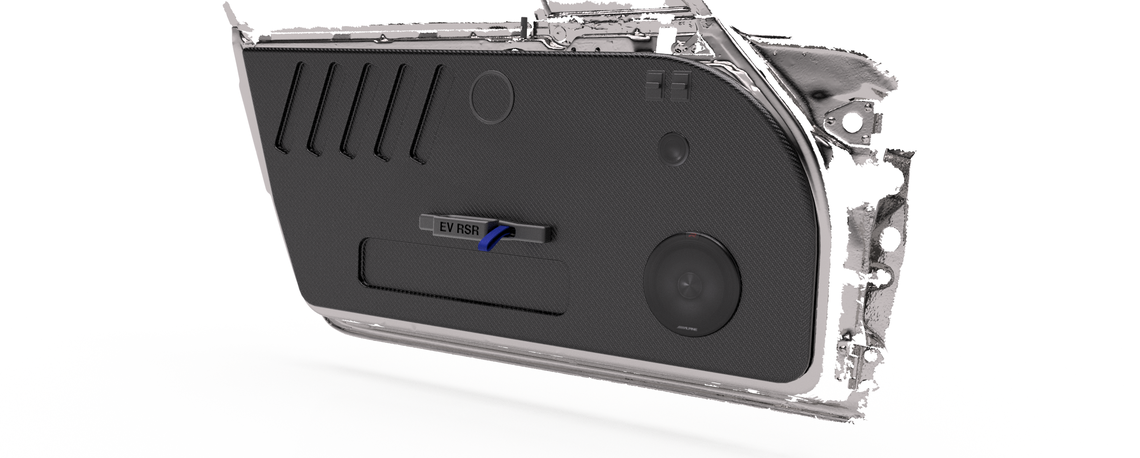

BREATHING LIFE INTO LEGACY

DOOR DESIGN EVOLUTION

Having captured every contour of the door's internal anatomy through our precise 3D scanning process, the thrilling phase of design and prototyping beckons. These scans, now seamlessly integrated into our Fusion 360 model, serve as the foundational canvas upon which we reimagine the doors of our Porsche 911 EV-RSR.

Function meets finesse as we carefully plot the incorporation of modern elements like speakers, a revamped handle, and an elegant strap, all while ensuring harmony with the car's innate structure. Our debut concept reflects a juxtaposition of past and present – a minimalist Carbon fiber inner design, luminous and streamlined, that pays homage to the classic by reincorporating certain iconic design fragments.

3D printed prototypes:

PROTOTYPING BATTERIES

WITH 3D PRECISION

The journey of our Porsche 911 EV-RSR transformation is advancing, albeit amid the hustle and bustle of bolstering our lab's manufacturing capabilities. A significant stride in our EV odyssey is conceptualizing the heart of the electric beast - the batteries. Instead of diving headfirst into battery acquisition, we've opted for a meticulous approach.

To optimize our space utility and determine the most efficient battery configuration, we're 3D printing battery prototypes. These tangible replicas, crafted on our Prusa 3D printer with the lustrous silver Prusa PLA Filament, will serve as crucial placeholders. They will guide our decisions on placement, orientation, cabling, mounting, and even the intricacies of liquid cooling.

THE COLOR OF STEVE MCQUEEN

Spring's Embrace: The Allure of Slate Grey

A Nod to Cinematic Royalty: The Iconic Slate Grey

In our mission to bring this masterpiece to life, we sought inspiration from a legend. Steve McQueen's final custom-ordered 911 Turbo boasted an enchanting slate grey hue—a color that resonated deeply with us as Californians with an insatiable passion for racing. This wasn't just any shade; it was a statement of style and heritage.

Navigating through the annals of automotive history to locate the precise color codes was no small task. Yet, determination led us to the elusive grey 6604 code, ensuring authenticity to our tribute. In the golden embrace of the Californian sun, the color radiates a distinctive brilliance. But a question lingered: would this captivating shade hold its allure in the contrasting, often stark, ambience of Northern Europe?